Introduction

This guide documents the design, fabrication, and assembly of a custom-built Diver Propulsion Vehicle (DPV) — a lightweight, modular, and efficient underwater scooter engineered for recreational diving and marine exploration.

The DPV project merges mechanical design, marine robotics, and electrical integration into a single, cohesive engineering build. It serves as both a functional underwater vehicle and a demonstration of applied systems engineering from CAD modeling to propulsion testing.

Design Overview

Purpose:

To develop a compact, neutral-buoyant DPV capable of propelling a diver or swimmer efficiently while maintaining high maneuverability and safety.

Key Design Features:

Weight: ~8 lbs (in air)

Max Speed: ~1.5 m/s (≈ 3 knots)

Runtime: 45–80 minutes (depending on throttle use)

Construction: Sheet metal frame + 3D-printed components

Control: Waterproof rotary throttle with magnetic kill switch

Power: Modular lithium-ion battery pack (4S or 6S)

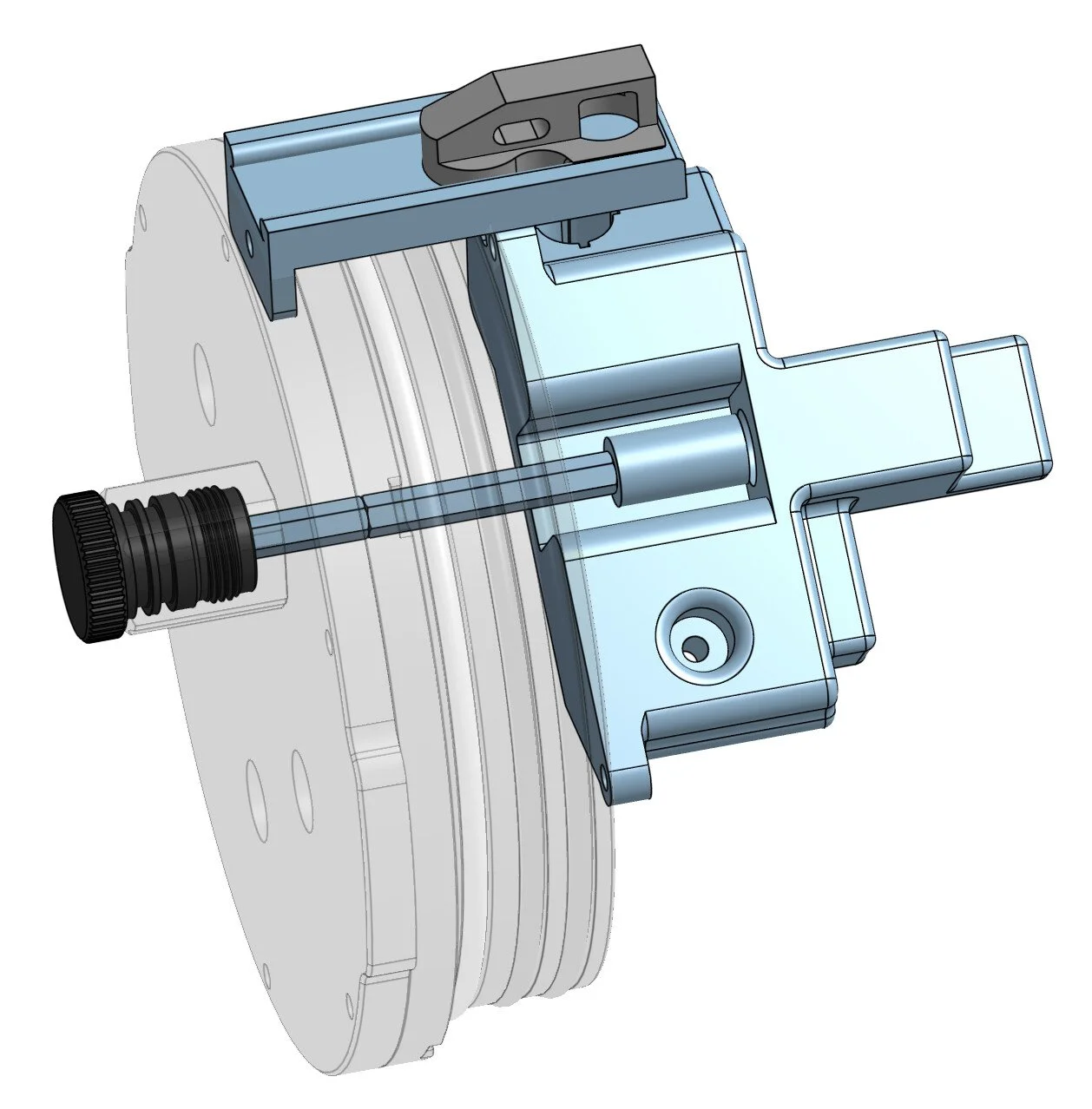

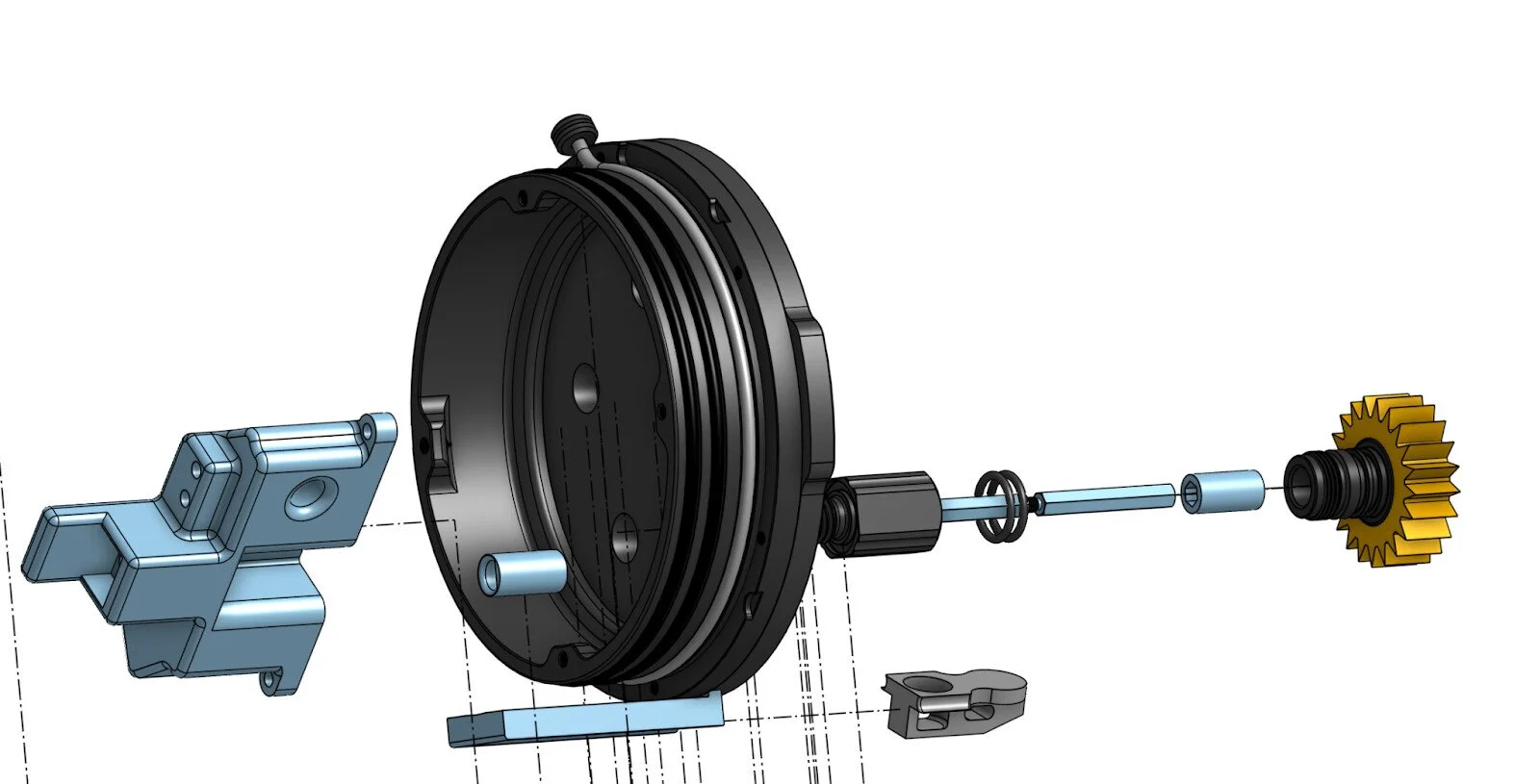

Mechanical Design

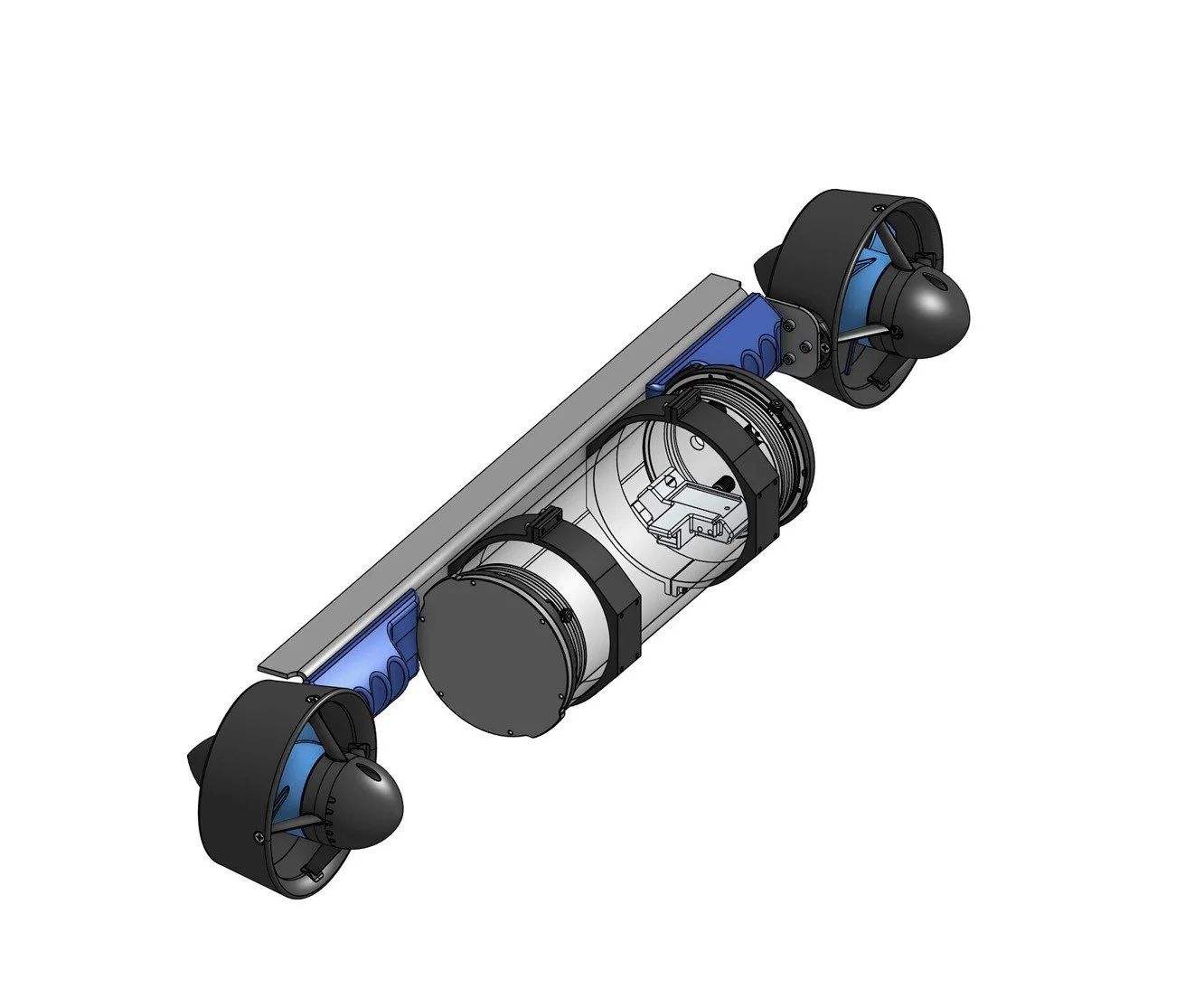

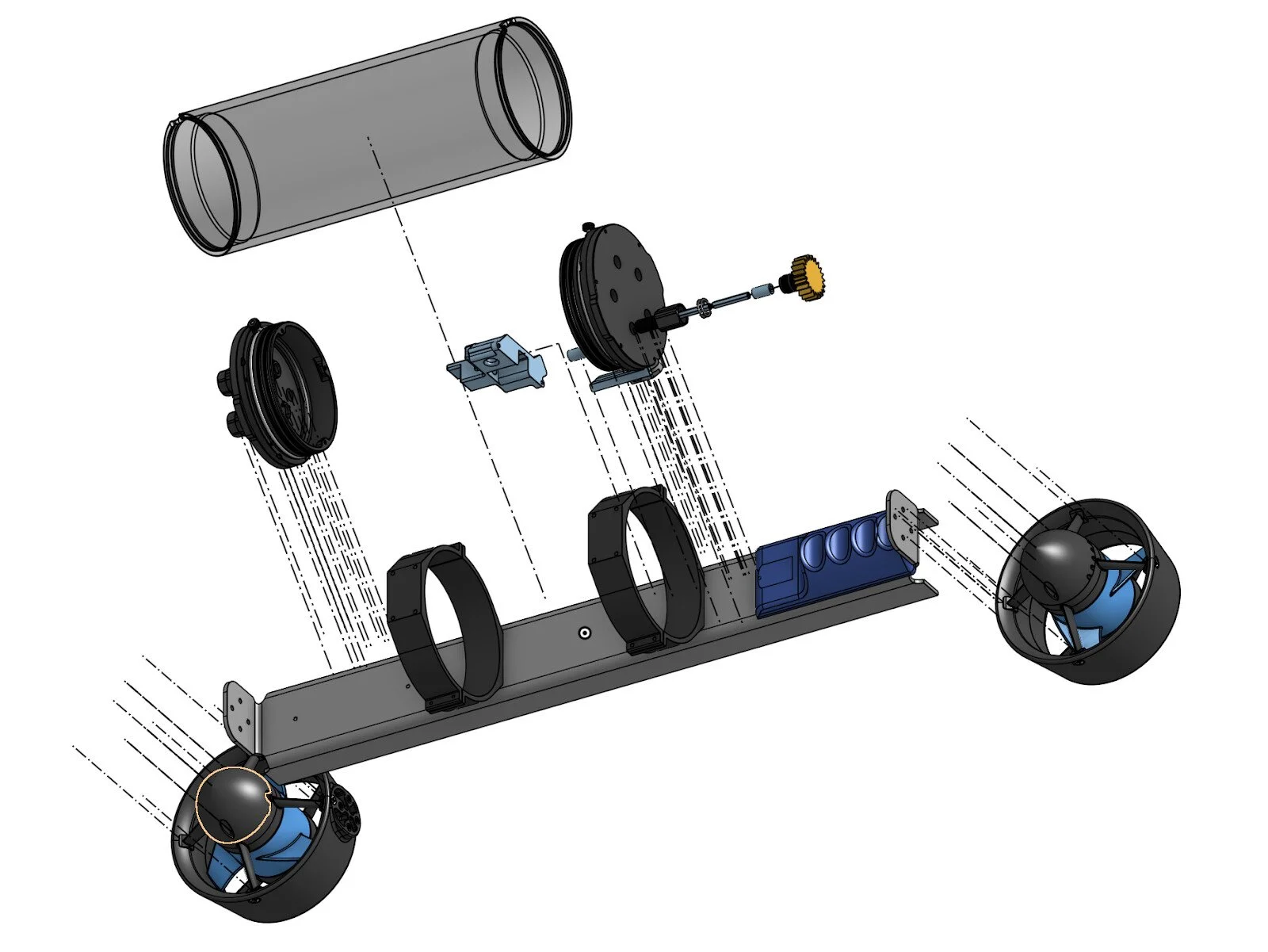

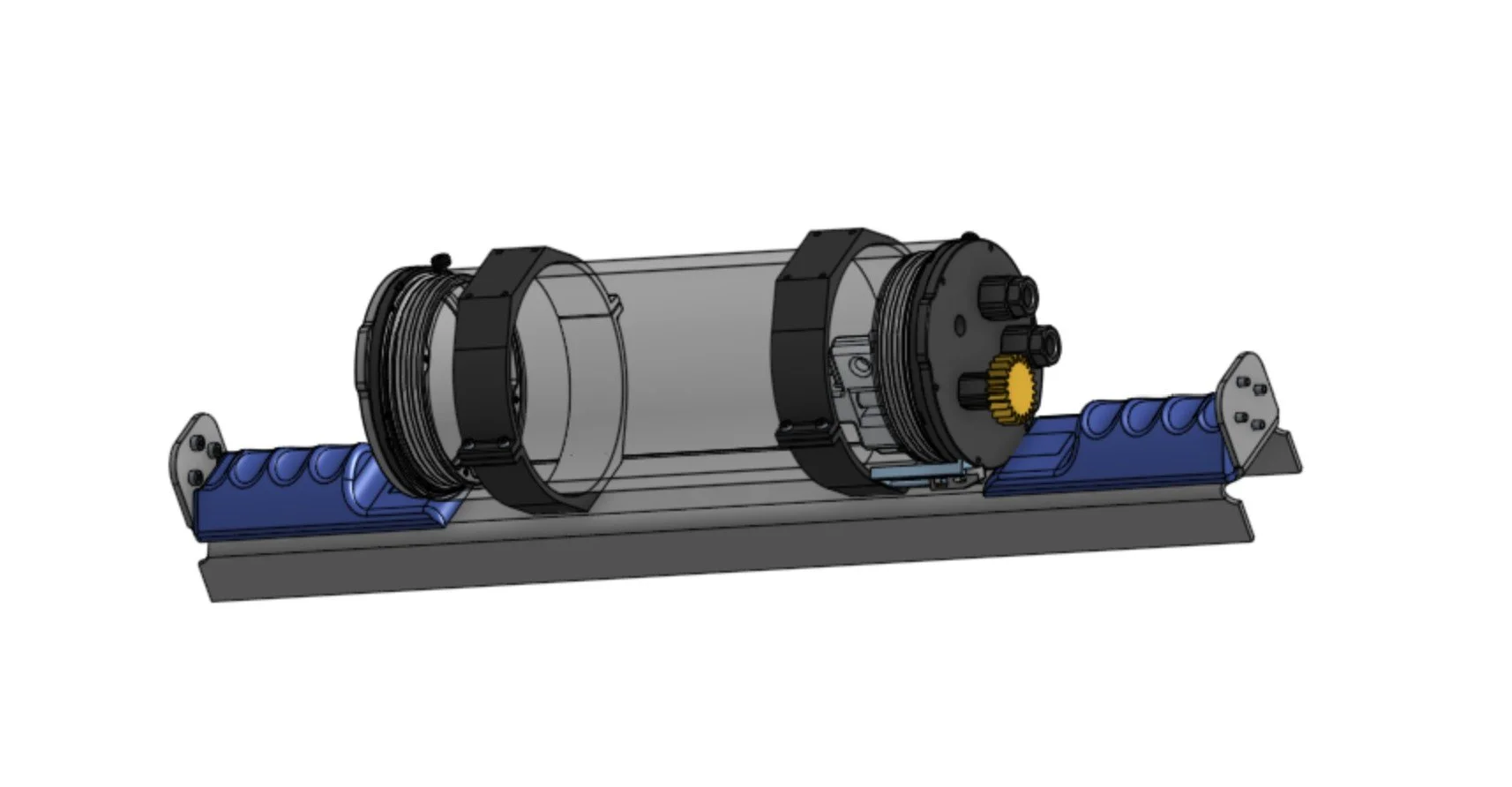

The frame evolved from a T-slot aluminum structure into a single folded aluminum chassis, which integrates the thruster mounts and enclosure supports.

Core Components:

Main Frame: 5052-H32 aluminum sheet, folded into a cross-bar assembly.

Enclosure: 4-inch acrylic or polycarbonate tube, sealed with dual O-ring flanges.

Handles: Ergonomic 3D-printed PLA+ grips, directly mounted to the frame.

Mounting Hardware: M3/M4 stainless bolts throughout, with printed alignment fixtures.

Design Software:

Modeled in SolidWorks, with all files available for iterative refinement and customization.

Manufacturing Methods:

FDM 3D printing (PLA+, PETG for structural parts)

CNC-machined aluminum coupling rings

Laser-cut sheet metal frame

Propulsion & Electrical System

Thrusters:

Dual Flipsky thrusters are used for balanced thrust. Props are mounted counter-rotating (CW/CCW) to cancel torque.

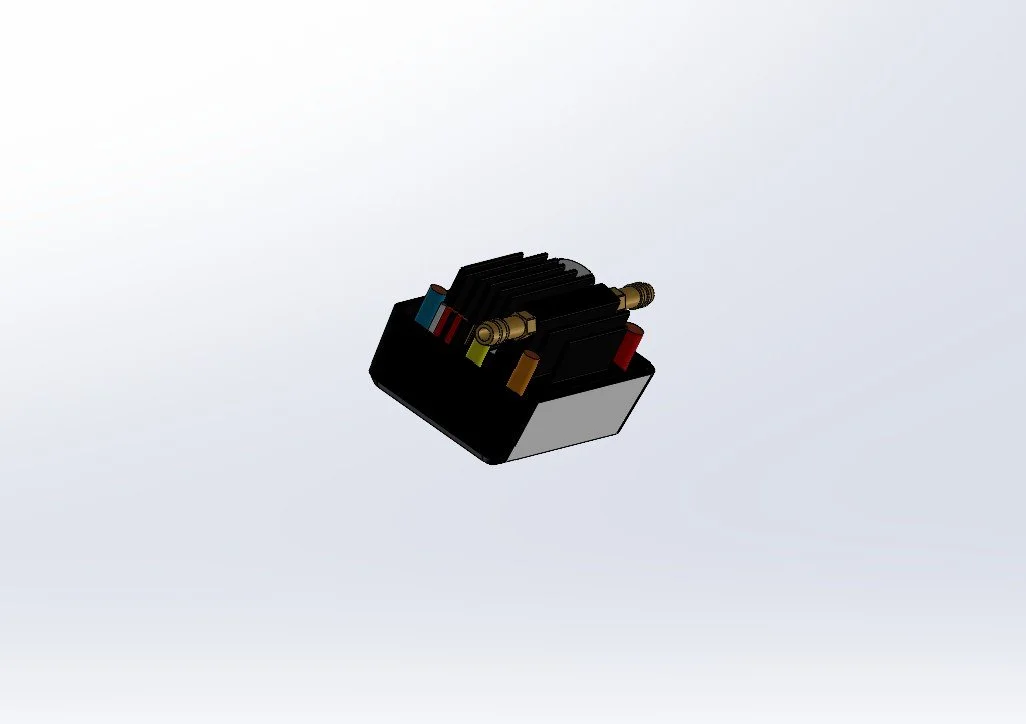

Electronics Layout:

ESCs: 2 × BasicESC or BasicESC 500 modules

Controller: Thruster Commander with potentiometer input

Kill Switch: Magnetic reed switch (lanyard-mounted safety cutoff)

Throttle: Waterproof rotary dial with mechanical coupling

Power Monitor: Inline volt/amp meter for battery tracking

Safety Controls:

Magnetic kill-switch automatically disables power when released.

Soft-start throttle logic prevents sudden torque spikes.

Fused battery input for circuit protection.

Wiring Summary:

10 AWG power lines to bus bar → ESCs → Thruster Commander

XT90 connectors for modular battery swaps

Waterproof penetrators (M10–M14) for cable management

Battery & Power Management

Battery Configuration:

4S 18Ah or 6S 22Ah lithium-ion pack

XT90 or XT60 quick-disconnect terminals

Inline power meter with total mAh tracking

Estimated Endurance:

Low-speed cruise (125–250W): 60–80 minutes

High-speed (~700W): 20–30 minutes

Voltage Safety:

Stop use when pack drops near 13V (4S) or 19.5V (6S)

Never discharge below 12V (4S) or 18V (6S) to prevent cell damage

Assembly Procedure

Mount Components

Attach thrusters to frame (props facing inward/upward for torque balance)

Secure enclosure clamps to frame

Install hand grips and hardware

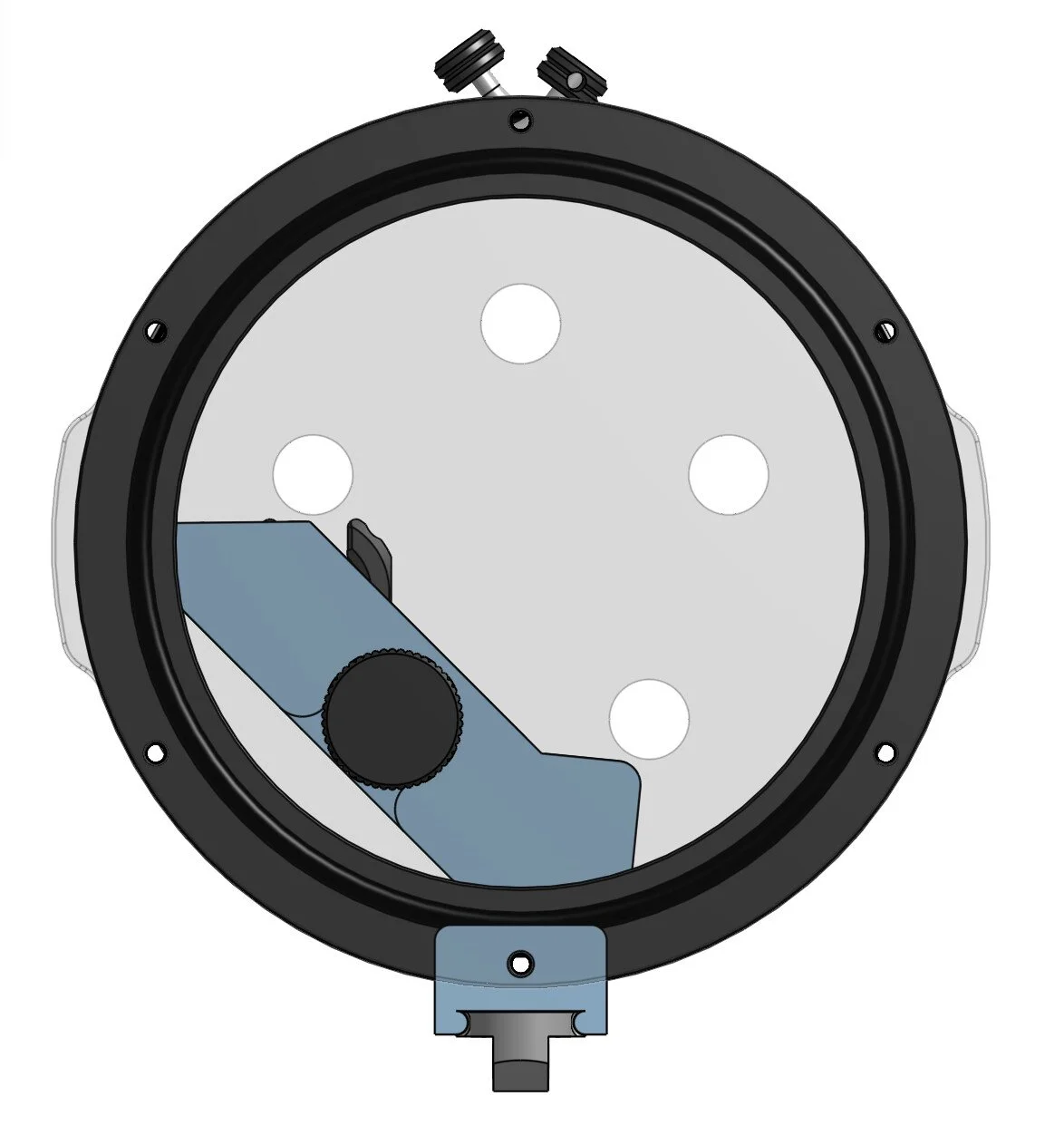

Prepare Enclosure

Mount Thruster Commander and potentiometer assembly

Wire ESCs and bus bar connections

Integrate reed switch and throttle dial coupler

Seal endcaps with O-rings, apply silicone lubricant

Install Electronics

Route thruster cables through M14 penetrators

Connect ESCs → Commander → Power meter → Battery

Test kill switch functionality

Final Integration

Compress O-ring seals, insert locking cords

Calibrate throttle range and kill switch engagement

Mount enclosure to frame clamps securely

Testing & Calibration

Pre-Dive Testing:

Verify thruster rotation direction (pushing away from frame)

Confirm ESC initialization tones

Ensure reed switch disengages motor on removal

Check voltage and mAh before submersion

Pool Validation:

Start at low throttle to observe thrust direction and buoyancy

Adjust ballast/foam to achieve neutral buoyancy

Conduct 10–15 minute endurance tests before open water trials

Safety Guidelines

Always use a buddy system when diving.

Avoid running thrusters out of water.

Never insert fingers or tools near propellers.

Remove magnetic kill switch before handling propellers.

Monitor voltage during use; do not exceed depth ratings of enclosures.

Avoid sand or silt near thrusters to preserve coatings.

Performance Goals & Future Improvements

Target Metrics:

Speed: 3–4 knots

Runtime: 45–60 minutes

Depth Rating: 30+ meters (testing phase)

Future Enhancements:

6S high-output power system for increased thrust

Integrated PCB for throttle and telemetry

Improved ergonomic hand grips

Mounting points for GoPro or navigation lights

Smart BMS with Bluetooth telemetry

Project Reflection & Purpose

This DPV project exemplifies the practical integration of mechanical, electrical, and marine design disciplines. It represents a holistic approach to hands-on marine engineering, blending rapid prototyping, materials testing, and safety-critical design in one platform.

Authored by: Colby Vreman

Project: Vreman 3D Lab — Diver Propulsion Vehicle Initiative

Status: Ongoing Development (In-Water Testing & Optimization)