“Exploring the space between problem and possibility through design, fabrication, and relentless iteration.”

Ideas Brought to Life

-

1967 Dodge D100 Restoration & Fabrication

A hands-on restoration project blending classic automotive craftsmanship with modern reliability upgrades. Work includes structural metal repairs, custom wood-lined bed fabrication, mechanical system overhauls, and electrical improvements. The build emphasizes precision fitment, improved safety, and subtle modernization while maintaining the truck’s vintage character. This ongoing project showcases my skills in fabrication, mechanical troubleshooting, and design execution across metal, wood, and automotive systems, demonstrating the ability to modernize legacy platforms while preserving their historical identity and addressing the practical challenges of integrating updated components.

-

1979 Datsun 280ZX Restomod & LS1 Powertrain Integration

A comprehensive restomod project focused on merging classic Datsun styling with modern V8 performance. This build replaces the factory inline-six with a GM LS1 engine and T56 manual transmission, requiring custom motor mounts, drivetrain fabrication, electrical harness redesign, and full fuel and cooling system upgrades. The project showcases advanced mechanical integration, wiring architecture development, and vehicle dynamics improvements through suspension, exhaust, and chassis modifications—resulting in a classic platform engineered for contemporary power, reliability, and drivability.

-

Diver Propulsion Vehicle (DPV)

A custom-built underwater scooter engineered for recreational diving and marine exploration. Designed around a lightweight folded-aluminum chassis with 3D-printed components, the DPV uses dual counter-rotating thrusters, a modular lithium-ion power system, and a waterproof throttle with magnetic kill switch for safe, intuitive control. The vehicle achieves neutral buoyancy, ~3-knot speeds, and up to 80 minutes of runtime, integrating sheet-metal fabrication, propulsion system design, and marine-grade electrical routing into a compact, serviceable unit. This project demonstrates applied systems engineering across mechanical, electrical, and marine environments—from CAD and fabrication to in-water testing and propulsion optimization.

-

SMUD California Solar Regatta — Solar-Powered Catamaran

Led the mechanical design of a solar-powered catamaran for the SMUD Solar Regatta, focusing on structural robustness, propulsion integration, and system-level coordination. Designed hull and drivetrain components in SolidWorks, performed FEA on motor mounts and transom joints, and developed modular brackets for rapid propulsion testing. Collaborated with the electrical team to integrate solar arrays, MPPT control, and a brushless motor system, while overseeing fabrication using machined aluminum, stainless hardware, and 3D-printed mounts. The completed vessel successfully competed in endurance, sprint, and slalom events, demonstrating efficient energy use, stable handling, and reliable mechanical-electrical integration.

-

Articulating Stingray Biomimetic Mechanism

A 3D-printed, gear-driven display piece that replicates the natural flapping motion of a stingray using mechanical linkages and rotational input. Designed and modeled entirely in SolidWorks, the system converts single-motor rotary motion into synchronized wing articulation through a central gear train and four-bar linkages. The wings consist of interlocking segments printed in PLA+ with flexible TPU/nylon bushings for smooth, low-friction movement. Powered by a compact battery and DC motor, the stingray operates for over two hours on a charge, demonstrating lifelike wave-propagation motion without servos or complex electronics. This project highlights biomimetic design, kinematic analysis, and precision 3D-printed mechanisms.

-

WALL·E Articulating Robot

A fully 3D-printed robotic platform inspired by cinematic character design, combining tank-tread mobility with expressive head and eye articulation. Built around a modular chassis modeled in SolidWorks, the robot integrates dual drive motors, servos for head and eye movement, and a rechargeable battery system controlled via wireless remote. Custom printed treads provide stable traction across varied surfaces, while a compact linkage system enables nuanced eye positioning, giving the robot a lifelike personality. Designed for modularity and future expansion, the project explores character mechanics, electromechanical integration, and playful motion design—bringing engineering and emotion together in a functional, animated machine.

-

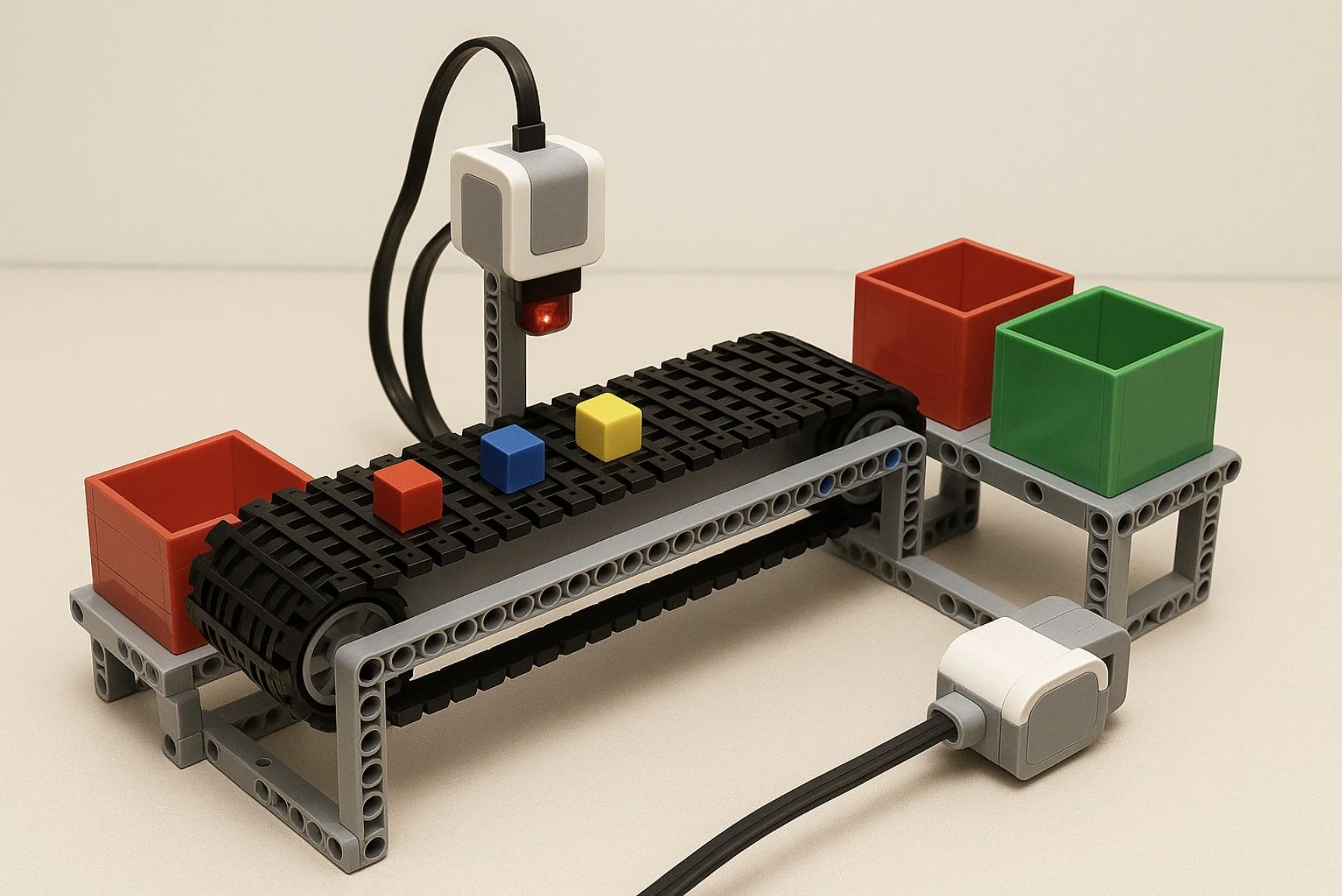

Autonomous LEGO EV3 Conveyor Sorting System

A programmable conveyor-based robot that identifies and sorts colored blocks into designated bins without human input. Built using LEGO EV3 components and Simulink-based control logic, the system integrates a tuned conveyor, color sensor, and pusher/diverter mechanism to manage material flow. The project demonstrates core automation concepts including sensor feedback, timed actuation, and modular mechanical design, resulting in a reliable sorting workstation that performs consistent classification under varying input conditions.